About

Girin Inc.

specializes in the design and manufacturing of AUTOLINK that

contribute to improved work productivity and worker safety in the construction machinery and heavy equipment sector.

Increase your work efficiency with new features and convenient equipment.

AUTOLINK provide the most innovative and systematic solutions in the construction machinery and heavy equipment sector.

Girin's AUTOLINK allow you to switch to almost all operational equipment in seconds from inside the cab.

History

- 2021. 10.13 Establishment of Girin Inc.

- 2021. 11 Started the supply of Self-lubricating bearings, gears and power transmissions parts

(Capa./mos 03,06 for rotators: 450 sets of worm and worm wheels, 300 sets of rotary joints, 300 hydraulic blocks x 6 types) - 2022. 03 Received a Youth Startup Grant from and signed a contract with the Korea SMEs and Startup Agency

- 2022. 07 Installed hydraulic testers for hydraulic rotary joints (0 ~ 900 bar)

- 2022. 11 Installed Worm grinding machines

- 2023. 03 Selected for the 13th Youth Entrepreneurship Academy (Busan) of the Korea SMEs and Startup Agency

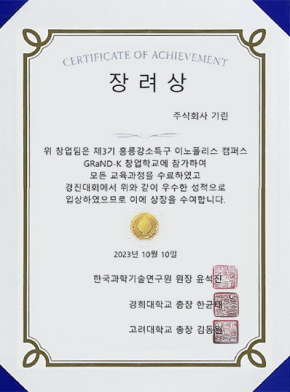

- 2023. 05 Selected as a GRaND-K Startup School for the Innopolis Campus Project in Hongneung SME Special Economic Zone, Seoul

- 2023. 08 Completed the development of automatic quick coupler device, AUTOLINK for excavators

- 2023. 10 Completed the GRaND-K Startup School at the Innopolis Campus Project in Hongneung SME Special Economic Zone, Seoul

- 2023. 12 Completed the 13th Youth Entrepreneurship Academy (Busan) of the Korea SMEs and Startup Agency

Core Value

-

Human Talent

People First

-

Safety

Girin believes in the safety of our products in both the manufacturing process and for our end-users.

The safety of our employees and customers is our top priority. -

Quality

From bolts to the finished products, we deliver the highest quality standards in all processes and aspects.

-

Sustainability

We devote all our efforts to ultimately contributing to the improvement and development of society and the industry we operate in.

Manufacturing

- Girin directly manages its design and manufacturing processes.

This allows us to guarantee quality and improve lead times with realiability. - We respond immediately to customer feedback to satisfy the ever-evolving requirements of our customers, thereby promoting improvements in product efficiency and safety as well as the competitive edge of our products.

- We constantly strive to develop new products to higher standards in collaboration with our customers and partners.

- Girin ensures full control over its entire chain from orders to product delivery.

Research and Development (R&D)

- Our R&D team focuses on the development, design, and manufacturing planning of our products.

- We develop and design most of our products in-house, from welded structures to programming of our own safety systems.

- We also implement our own test equipment to test and validate our designs.

- We utilize 2D and 3D CAD software for design and calculations, while operating our own ERP system.

This allows us to be closer to our customers and more flexible in responding to their demands and requests.

We aim to become a global leader with innovative technologies in the field of construction machinery attachments.

Quality

- We aim to create quality attachment equipment that exceeds our customers' expectations.

- All products are completed in accordance with well-defined design specifications, while in-house manufacturing and assembly ensure compliance to these requirements.

- We strictly adhere to delivery deadlines, while ensuring communication in advance for unavoidable circumstances.

- We set measurable quality targets each year, and manufacture our products using established, state-of-the-art processes to avoid rework or defects.

- We select trusted partners with well-defined criteria.

- We clearly define our quality requirements, by which we regularly evaluate our suppliers.

- We continuously improve our business processes and management systems based on customer and employee feedback.

- Our aim is to deliver premium products that embody both quality and customer satisfaction.

Quality Policy

Quality is an integral attitude and behavior we strive toward in our manufacturing process. To execute our quality requirements, we have set clear standards and policies to deliver on our key values.

We realize a virtuous circle in which our employees and partners produce safe high-quality products, customers offer insightful feedback, and our follow-up research and improvements work toward better quality,

we will be able to deliver the highest quality and in turn gain customer trust.

- We ensure safety and follow our defined principles.

- We objectively validate our products through thorough simulation and demonstration. We always make informed and fact-based decisions and do not compromise with the unknown.

- We constantly listen to our customers and monitor new requirements, future needs, and market trends.

- We have implemented a systematic product development process that will help create added value for our customers.

- We comply with applicable laws and regulations.

- Manufacturing of defective products is stopped before such products can reach the next stage of the process.

- In the unlikely event that something goes wrong, we will swiftly take any necessary action and will thoroughly review, learn and improve to prevent repeated incidents.

Safety and

Environmental Awareness

AUTOLINK equipment allows customers to save time and money by making it easy to replace a wide range of different attachment devices.

- Most often, accidents occur when the operator has to climb in and out of the cab.

- Installing an AUTOLINK on an excavator minimizes such risks since the operator rarely has to leave the cab.

- Without the need to jump out of the cab, operators are not exposed to the risks of injuring their knees and backs.

- At the same time, this ensures fewer people in the danger zones of the machines.

Since operators no longer need to connect and disconnect hydraulic lines by hand, potential health risks, such as allergies and breathing difficulties caused by frequent contact with hydraulic oil, can be eliminated.

- Whenever replacing attachment devices in the traditional manner, workers are exposed some hydraulic oil leakage.

- AUTOLINK is equipped with a flat coupling.

This coupling eliminates oil leakage, helping to make the work site more environmentally friendly. - AUTOLINK system hoses are located close to the excavator stick, to better prevent wear and tear.

- The hose routing also has the advantage of reducing the replacement frequency of damaged lines, which helps to reduce environmental pollution.

Warranty and

Customer Service

Providing customers the highest level of support is our top priority.

- Our technicians have the knowledge and skills to get the job done.

- We always strive to deliver to the needs of our customers.

- You can find our service manuals, installation manuals and brochures.

-

Read about the terms of our warranty. Go read the warranty terms

If you leave any questions, we will answer them as soon as possible.